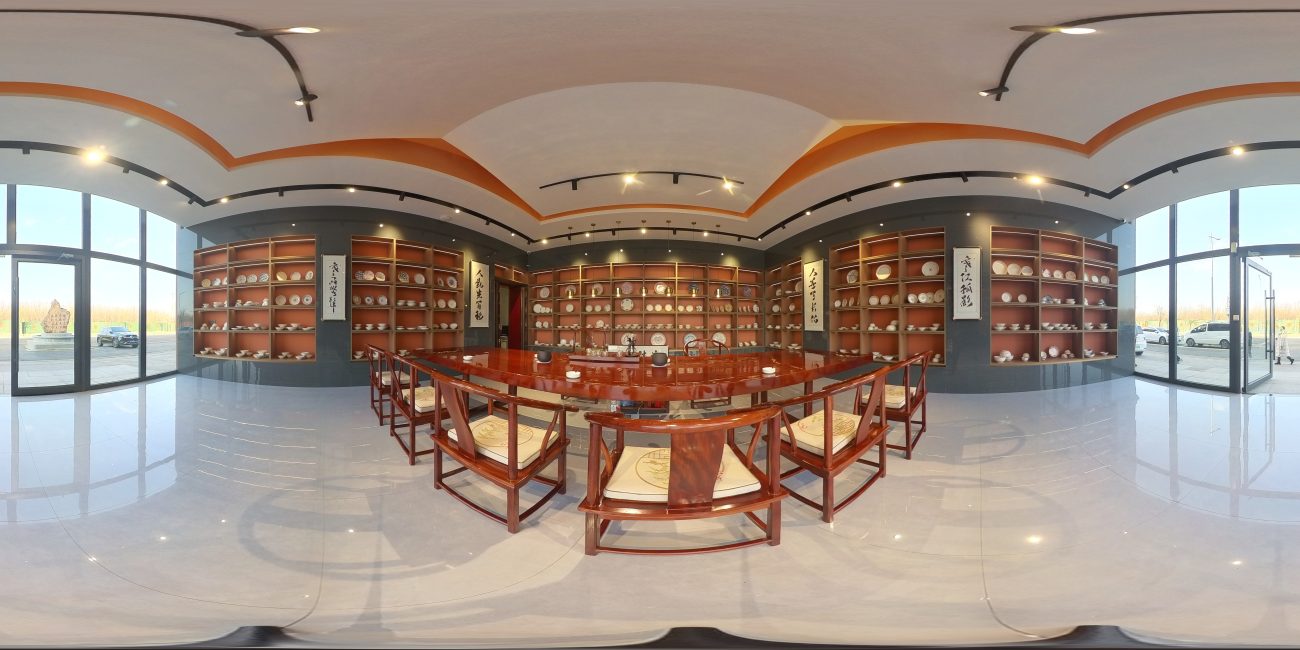

We are a store specializing in high-quality ceramics.

Our Passion

Our passion for ceramics drives us to provide the highest quality products and exceptional B2B customer service.

Our Service

We are always customer-centered, focusing on details and quality, striving for excellence in every product

About our online factory

Leciceramic is dedicated to providing high-quality custom reinforced ceramic products for B2B clients worldwide. Located in Ying County, Shuozhou City, Shanxi Province, our company is equipped with advanced production facilities and a skilled technical team, committed to offering comprehensive customized solutions.

Our factory covers an area of 40,000 square meters and features 8 automatic rolling production lines, 20 printing machines, with a daily production capacity of up to 200,000 pieces. Additionally, we have a 100-meter-long roller kiln, ensuring efficient production for large-scale manufacturing needs.

We work through every aspect at the planning

Customizing Excellence, Shaping Taste!

Our products cater to a wide range of B2B custom needs and are widely used in industries such as catering, hotels, and gifts. We offer a variety of customizable options in terms of color patterns, styles, and sizes to meet the unique needs of our clients. Our company boasts a team of 10 experienced foreign trade professionals who are dedicated to expanding our international market and providing efficient, high-quality service to clients worldwide. Whether you are looking for high-quality custom ceramic products or flexible production solutions, we provide comprehensive support and solutions.

About Our Auto-Process

Max 20,0000pieces one day

Raw Material Selection

The process begins with carefully selecting high-quality clay to ensure the ceramic products are durable and strong

Milling & Blending

The clay is crushed and thoroughly mixed to achieve a consistent texture, preparing it for shaping

Clay Forming

The clay mixture is molded into raw forms, creating the basic shape of the ceramic dinnerware

Automated Clay Shaping

The raw clay forms are fed into automated machines that refine and perfect the shape, ensuring consistency and precision in every piece

Automated Molding

The clay forms are automatically separated and placed into molds, where they take on their final shape with precision and efficiency

Automated Molding Process

The raw clay forms are placed into molds where the automatic system applies pressure to shape them into precise ceramic dinnerware pieces

Edge Trimming

The automatic system trims and smooths the edges of the dinnerware to remove any roughness, ensuring a clean and refined finish

Pattern Printing

Using advanced printing machines, intricate patterns and designs are applied onto the surface of the dinnerware, adding aesthetic details

Automated Glazing

The ceramic pieces are automatically coated with a smooth glaze, enhancing their appearance and durability while ensuring uniform coverage

High-Temperature Firing

The ceramic dinnerware is placed in a high-temperature kiln, where it is fired at extreme heat to harden the material and finalize its shape